GreenroomVoice had the pleasure to provide ideas, content and contacts for a truly innovative format: The Globetrotter Innovation Lab located in their new “Berliner” flagship store.

The Innovation Lab presents manufacturers, brands and products that are leading the way to a circular future: if all processes are connected the gaps of the cycle can be closed. Piece by piece, pragmatically and effectively, in all areas of the value chain.

2021 was a special year without the usual hustle and bustle of the typical tradeshows and therefore also without our signature showcases- almost! This time gap gave us the opportunity to shine the spotlight on our favorite ideas, processes and products, thanks to Globetrotter. And this is what we love doing most: offer our support and expertise to those who provide positive change.

Our world today is 8, 6% circular. That means: Only 8.6% of all human products are kept in a cycle of reuse and further use today. The rest is disposed of, natural resources are lost and valuable raw materials are destroyed, which are the basis for new growth – both ecologically and economically.

The outdoor industry makes up only a fraction of the textile industry with approx. 0.23%. Nevertheless, the innovations that emerge from this particular branch of the textile business often have a lasting impact that has the potential to change the entire industry.

Our exhibition “The Circular Future” shows how much potential there can be in an outdoor innovation. And where gaps have to be closed by these pioneers in order to shape a viable future.

The world’s first 100% recyclable ski. Made possible by a hidden component: the adhesive. The bio-based epoxy-resin mixture can be dissolved again after the usage phase. Thanks to this innovation, all processed materials can be sorted according to type and recycled.

Every earlybird ski has been a completely circular product since 2021: made entirely from recyclable materials, some of which have already been recycled. The special feature is the soluble epoxy resin technology. They allow previously inseparable composite materials to be sorted and all processed materials can be returned to existing recycling streams. This innovation turns what was previously waste into a new raw material. This innovation could be extended to all bonded composites – from the sports to the automotive industry. A true game changer.

More on Earlybird Skies at GreenroomVoice

More on Earlybird Skies

Imagine that in the future you will not buy a product, but a material – in the form of a product. A material from which new products are created again and again.

The Finnish start-up Spinnova and Bergans have found a way to produce a textile fiber from a natural, renewable raw material that can be recycled to itself again and again without being chemically treated. Combined with a business model that sells not just a product, but a proportion of a total amount of material, a single piece of material can be converted into new products over and over again. A backpack can be turned into a jacket – with low ecological and monetary costs.

More on the Spinnova concept at GreenroomVoice

More on Bergans & Spinnova

Why cultivate new cotton plants when you can use the tons and tons of cotton material that end up in the trash every day?

With the REFIBRA ™ technology, the Austrian supplier Lenzing uses a previously unused resource: cuttings from post-industrial waste. The result is a regenerated cellulose fiber from which new clothing is made, that is not only made from certified wood, but also from cotton scraps that would otherwise be burned.

On the one hand, this reduces the amount of post-industrial waste, on the other hand, it reduces the use of new raw materials. Considering the quantities occurring on both sides, this holds an enormous potential.

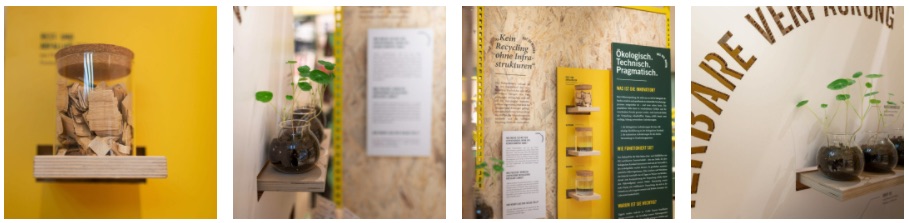

This is the only plastic-free film packaging in Europe that is 100% biodegradable. Made from residual and wood waste from FSC-certified forestry, the packaging is completely compostable within 42 days and is free of harmful substances. Repaq Cellulose is certified by TÜV as “home and garden compostable” and thus meets the currently highest environmental standard for film packaging worldwide.

The Repaq film packaging is not only 100% biodegradable, but can also be easily integrated into industrial processing processes. The plastic-free film can be used in different sizes and for different purposes. Even when printed, the packaging remains free of harmful substances.

Every day around 75,000 tons of fertile humus are destroyed worldwide – the basis of our food. Microplastics and plastics find their way into the soil and oceans. The return of Repaq’s cellulose-based packaging to the biological cycle leads to the formation of new nutrient-rich humus and thus to the possibility of renewed raw material extraction. This innovation closes an elementary gap in the cycle: from the end of a product’s life to the extraction of the raw material required for it. So that this can also happen on a large scale, a compost infrastructure must now be requested from the large waste disposal companies.

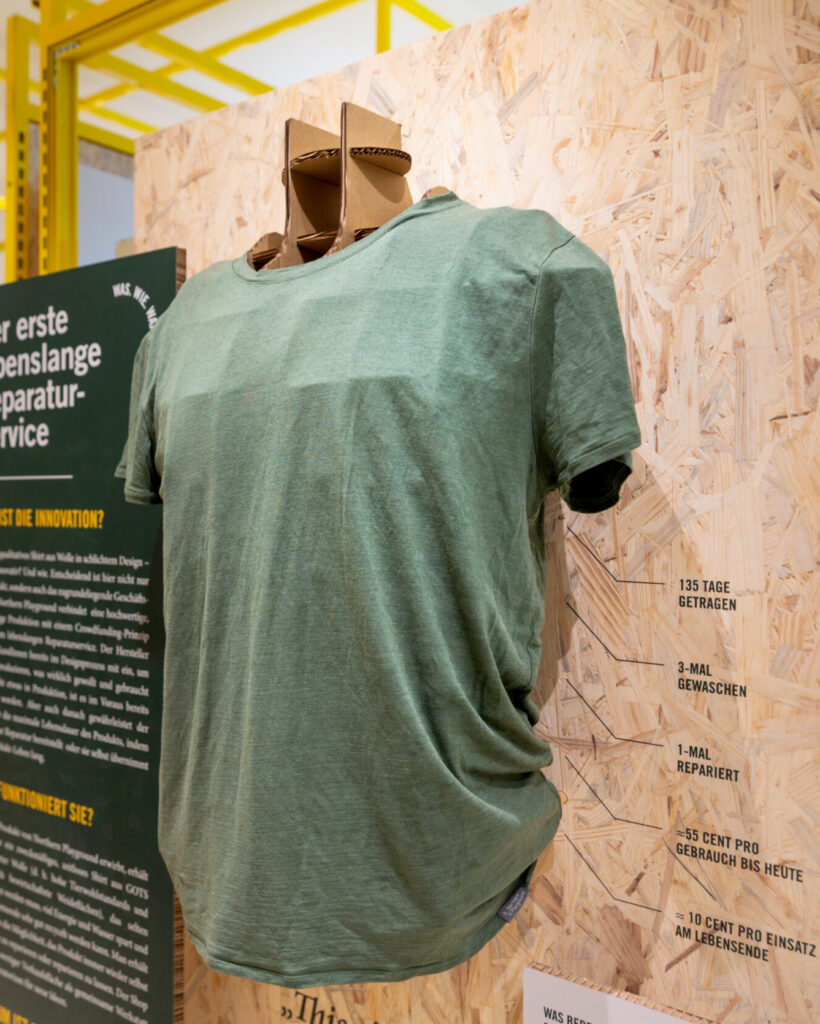

Responsibility instead of overproduction: Northern Playground takes responsibility for itself and its customers. Only what was previously ordered is produced. End users already take part in the design process and receive a lifetime repair guarantee for every product. Items from the shop in Oslo are not for sale, but for joint creation and repair. All this is guided by one question: How to do business more sustainably?

Northern Playg round combines high quality, sustainable production with a crowdfunding principle and a lifelong repair service.

“You need to buy less clothes” – for Northern Playground this is neither a slogan nor a contradiction. The whole concept of the Norwegian brand aims to preserve small quantities of materials for a long time. Sustainable raw materials combined with simple, timeless functional designs. Production is not seasonal, but only after sufficient demand and advance orders. In addition, Northern Playground came up with a completely newly used retail space. The brand shows that not only the product can be rethought but, above all, how it is used.

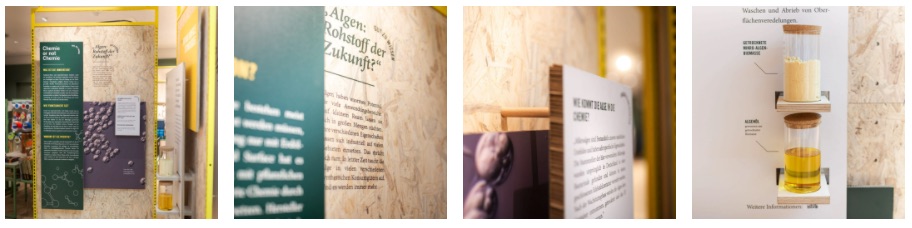

This is a vegetable textile finishing that using a 100% natural chemical harvested from microalgae. With miDori®, Beyond Surface has developed a sustainable surface treatment for textiles and thus solves an underestimated problem: the contamination of the environment through washing and abrasion of surface finishes.

Functional shirts and sports underwear are mostly made of synthetic fibers that have to be chemically treated in order to conduct moisture. So far, this has only been possible with petroleum-based chemicals. Beyond Surface has managed to achieve the same performance with plant-based raw materials and replaces the petroleum-based chemistry with regenerative synthetic raw materials. This enables manufacturers to refine their synthetic fiber textiles with an ecologically harmless chemical without having to change the manufacturing process. The result is a surface refinement that does not pollute the environment through production, washing or abrasion.

One material, one piece of cloth, almost zero waste. The Cyclon closes the circle by not being sold in the first place. Maximum recycling, ensured by a unique take-back principle: the running shoe is not sold, but rented out in a leasing model. When he has reached it’s end of life, it is exchanged for a new pair. The used shoe can be 100% recycled for re-manufacture.

With a subscription model, ON ensures that every shoe in the Cyclon series is fed back into its own recycling cycle. The manufacturer remains the owner, receives his products back after the usage phase and can recycle them 100%. The cyclone is designed to be circular from the ground up. It consists of two polyamides that can be recycled together, which meets both the technical performance and the requirement for maximum recyclability.