The Lenzing Group, producer of fibers from botanic origin, offer a sustainable solution model in the sense of natural circular economy. Turning cellulosic fibers into a luxuriously soft blouse on a boutique rack or a smart sports outfit with perfect thermal regulation involves numerous stages and specialists. More often than not, these stages and specialists are rather disconnected. This is where Lenzing plays a key role by doing much more than supplying fibers.

Solutions sourced from sustainably forested wood are unique: No other raw material is as beneficial to our planet when it comes to meeting a growing population’s demands and preserving resources at the same time. As soon as a tree starts to grow it begins to protect our environment – by absorbing CO2 greenhouse gas to an extent that otherwise only our oceans can manage.

The Lenzing Group, a recognised leader in climate action, member of the CEO Climate Leaders Group of the World Economic Forum and a signatory to the United Nations Fashion Industry Charter for Climate Action, will drastically reduce its CO2 footprint. The Lenzing Group will invest extensively over the coming years to reduce carbon emissions both inside its operational boundaries (scope 1+2) and in its supply chain (scope 3). Due to its ambitious CO2 emission reduction strategy, the Lenzing Group will further contribute towards helping customers to transition their business to a lower CO2 base.

A first milestone is set for 2030, when Lenzing plans to reduce CO2 emissions per ton of product by almost 50 percent (scope 1+2 and 3) compared to a 2017 baseline. The total CO2 reduction of all the planned initiatives will yield 1.3 million tons (Mt).

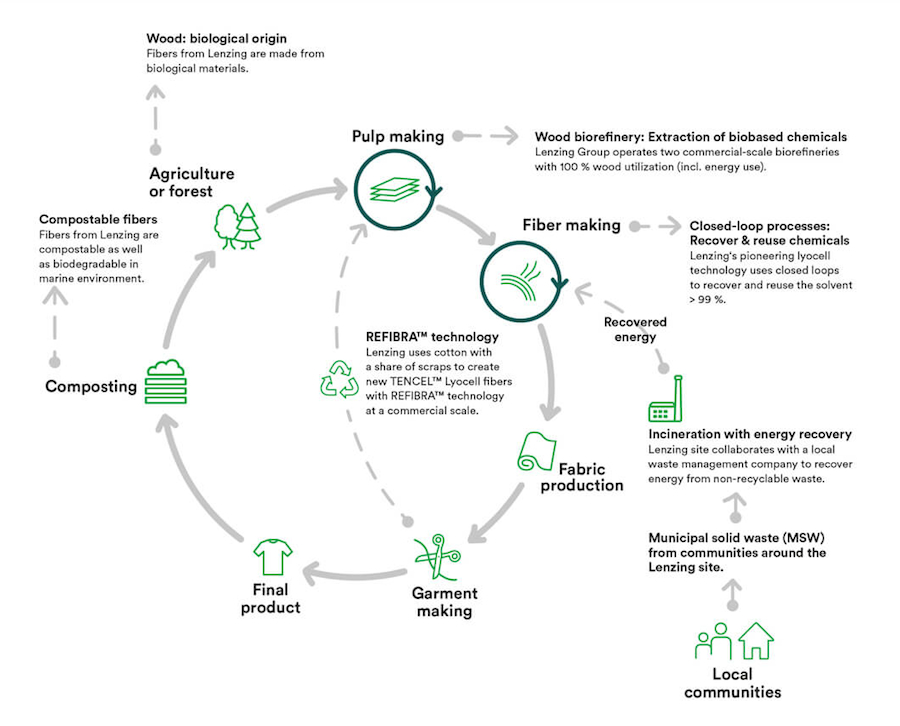

In the emerging circular economy of the future, nothing is treated as waste. What is left over from one process becomes input to another, so keeping it circulating – protecting the environment.

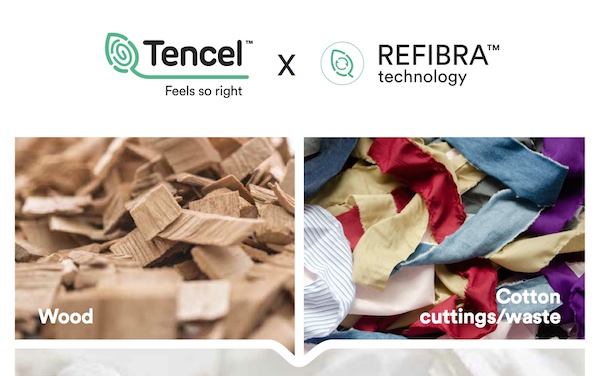

REFIBRA™ technology gives a second life to pre-consumer cotton waste from garment manufacturing – which would otherwise be sent to landfills or incinerated – by upcycling it into brand new cellulosic fiber materials for clothing and home products.

Using the award-winning efficient closed loop production process, TENCEL™ lyocell fibers produced with REFIBRA™ technology use 95% less water to produce than conventional cotton, with high resource efficiency and low environmental impact.

TENCEL™ lyocell fibers with REFIBRA™ technology are produced from a mix of wood pulp from sustainably managed forests with up to one third of pulped cotton scraps. With both raw materials originating from plant sources, the resulting fibers are 100% bio-based.

Tuesday 02-07-2019 @ 11:00am CSR HUB – HALL B6

Representatives of brands and organisations will be there personally to speak about their projects, product and achievements. If you are curious about the latest developments in this exciting and challenging field you are welcome to join us!

DAILY GUIDED TOURS:

SUNDAY 30.06.2019:

HDWool, Light My Fire, Nikwax, Re:Down

MONDAY 01.07.2019:

American Wool, Fluidsolids, Lavalan, myclimate, VAUDE

TUESDAY 02.07.2019:

Beyond Surface Technologies, Lenzing, Royal Robbins, Südwolle Group, Textile Exchange

WEDNESDAY 03.07.2019:

Hohenstein